What Are The Gearbox And Gear Reducer

Release time:

2024-07-16

A comprehensive guide to gearboxes and gear reducers in the machinery industry, explaining their importance, types, applications, and benefits. Learn how these components improve efficiency, control, and equipment lifespan.

1. Introduction

Gearboxes and gear reducers are indispensable components in the machinery industry, serving the vital function of transmitting power and changing the speed or torque of mechanical systems. They are important to the manufacturing, automotive and aerospace industries. Without these components, machinery would not be able to function effectively and efficiently.

This article aims to provide a comprehensive understanding of gearboxes and gear reducers, explaining their fundamentals, types, applications and benefits. This article will help the reader to get a clear understanding of how gearboxes and gear reducers can help achieve better performance in mechanical equipment.

2. What is a Gearbox or Gear Reducer?

A gearbox or gear reducer is a machine that converts speed and torque from one rotating shaft to another. Its main job is to ensure good functioning of mechanical equipment by providing the correct ratio of speed and torque.

2.1. Definition of a Gearbox or Gear Reducer

A gearbox or a gear reducer consists of gears and shafts that work together to transmit mechanical power. Gearboxes and gear reducers adjust the speed and output torque of a rotating shaft by mounting gears of different sizes together.

2.2. Working Principle of Gearboxes and Gear Reducers

A gearbox or gear reducer varies the speed and torque from the input shaft to the output shaft by meshing gears with different numbers of teeth together. The input shaft rotates and drives the gear system, which varies the speed and torque at the output.

2.3. Different Types of Gearboxes and Gear Reducers

There are many types of gearboxes and gear reducers made for specific uses and needs. The common types of gearbox and gear reducer are helical reducer, parallel shaft reducer, planetary reducer, and worm reducer, etc.

-

Helical Reducer: This type of reducer transmits power between parallel shafts. The teeth of helical gears are cut at an angle to the gear axis, which allows the gearbox to operate more smoothly and quietly than spur gears. If you are interested in the helical gearbox and gear reducer, please check out our website MD Series Helical Gear Reducer to get a perfect helical gearbox and gear reducer solution for your requirements.

-

Parallel Shaft Reducer: This kind of reducer's gears are established on shafts parallel to every different. It is appropriate for machines and equipment that require high torque. If you are interested in the parallel shaft gearbox and gear reducer, please check out our website MP Series Parallel Shaft Helical Gear Reducer to get a perfect parallel shaft gearbox and gear reducer solution for your requirements.

-

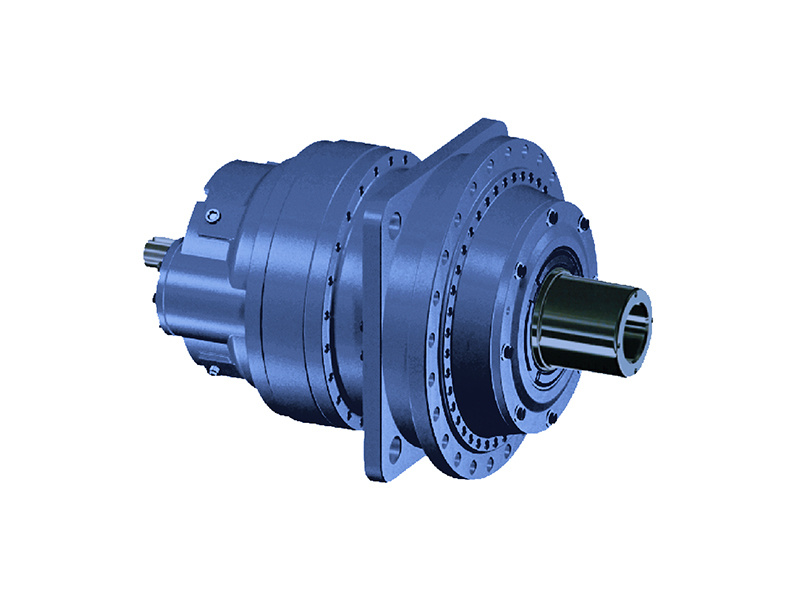

Planetary Reducer: This reducer has solar tools within the center and several planetary gears around it, all within outer ring tools. It could be very efficient and usually has a small volume. If you are interested in the plantary gearbox and gear reducer, please check out our website P Series Plantary Gear Reducer to get a perfect plantary gearbox and gear reducer solution for your requirements.

-

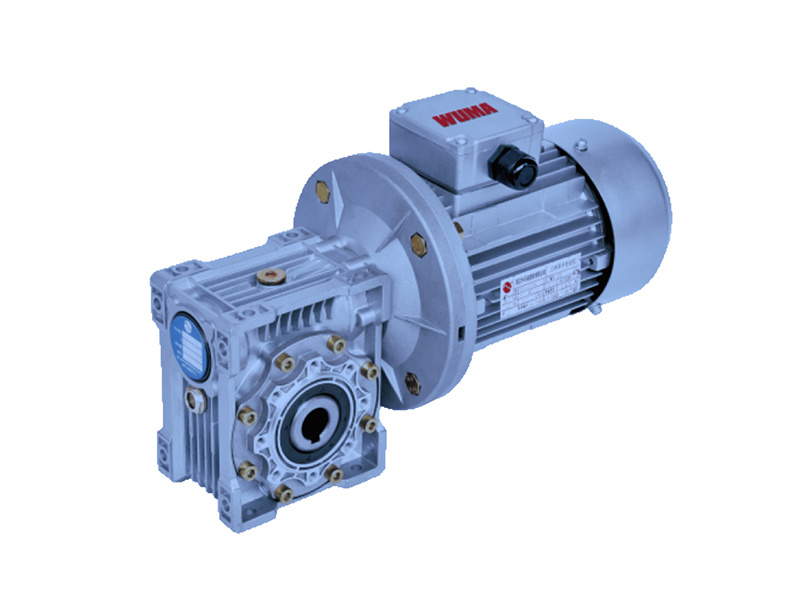

Worm Reducer: This type of reducer uses worm gears to drive a worm wheel. It provides high output torque when the operation speed is low. If you are interested in the plantary gearbox and gear reducer, please check out our website NMRV Series Worm Gear Reducer to get a perfect worm gearbox and gear reducer solution for your requirements.

Understanding the function of specific gearboxes and gear reducers is important for choosing the type of gearbox for machines and ensuring their performance.

3. Benefits of Gearboxes and Gear Reducers

3.1. Importance and Need for Gearboxes and Gear Reducers

Gearboxes and reducers are important for machines and equipment which are widely used in many industries. Gearboxes and reducers are intermediaries between the power source and the driven component, helping speed and torque conversion meet specific operational requirements. With gearboxes and reducers, many machines would be able to operate efficiently.

3.2. Benefits of Gearboxes and Gear Reducers in Machinery and Equipment

-

Increased Efficiency: By adjusting speed and output torque, gearboxes and gear reducers improve the power transmission system to meet the machines' operational requirements. This increases efficiency, reduces energy consumption, and improves machines' overall performance.

-

Improved Control: By using gearboxes and gear reducers, operators can better control the speed and direction of machinery.

-

Extended Equipment Lifespan: By distributing the loads, gearboxes and gear reducers minimize mechanical components' wear and tear, thus extending the equipment's life and reducing the frequency of maintenance and repairs.

-

Reduced Noise: The gearbox and gear reducer help reduce the noise level when the machine is in operation, which helps create a quieter working environment.

3.3. Essential Applications of Gearboxes and Gear Reducers

The gearboxes and gear reducers have a wide range of applications. You can access the application of the gearbox and gear reducers from our website Applications from Official Website. Here, I list several industries for reference.

-

Manufacturing: Gearboxes and gear reducers play an important role in a variety of manufacturing operations such as conveyor systems, packaging machinery and CNC machine tools. They enable precise control of production equipment, increasing productivity and product quality.

-

Renewable Energy Industry: Gearboxes and gear reducers are vital to wind turbines and solar tracking systems. They help convert the rotational motion of wind or solar energy into electricity by regulating speed and torque for optimal power generation.

-

Construction: Gearboxes and gear reducers are used in construction machinery such as cranes, excavators and bulldozers to meet the speed and power requirements of different operations. They ensure the power transmission's efficiency and heavy equipment's smooth operation.

All in all, gearboxes and gear reducers are beneficial to mechanical equipment and are key to optimizing machine performance and efficiency. Understanding their significance and applications across a wide range of industries emphasizes the importance of choosing the right gearbox and Gearmotor solution for specific operational needs.

4. Choosing the Right Gearbox or Gear Reducer

4.1. Factors to Consider in Gearbox Selection

When selecting a gearbox or gear reducer for a specific machine, there are several key factors to consider to ensure machine performance:

-

Speed and Torque Requirements: Determine the speed and output torque specifications required for the machine and equipment.

-

Power transmission efficiency: Consider the service factors and efficiency ratings of different types of gearboxes to select the one that provides the best power transmission efficiency for the machine.

-

Environmental Conditions: Evaluate the environment in which the gearbox will be used. Consider factors such as temperature, humidity, and exposure to contaminants that may affect the performance and shorten the life of the gearbox.

-

Space Constraints: Consider the space in which the gearbox or gear reducer will be mounted.

-

Maintenance: Evaluate the ease of maintenance and availability of spare parts for the selected gearbox to improve the ease of future maintenance and repair.

4.2. Importance of Sizing and Compatibility

Correct sizing and compatibility are key factors when selecting the gearbox or gear reducer for the machine or equipment:

-

Correct Sizing: Ensure the gearbox and gear reducer is adequately sized to handle the required speed, output torque as well as power levels.

-

Alignment: Proper gearbox and gear reducer alignment with the driven and driven components is important to prevent gearbox wear and noise and power transmission efficiency reduction.

-

Compatibility with components: Verify that the gearbox or gear reducer is compatible with other mechanical components in the system, such as motors, shafts and bearings, to ensure smooth operation and durability.

-

Lubrication and Cooling: Consider the lubrication requirements of the gearbox and gear reducer and ensure that proper cooling mechanisms are in place to maintain optimal gearbox operating temperatures and prevent premature component damage.

4.3. Tips for Optimal Performance and Longevity

To maximize the performance and life of your gearbox or gear reducer, consider the following tips:

-

Regular Maintenance: Implement a regular maintenance program to inspect, lubricate and replace worn parts in the gearbox to extend the life of the gearbox or gear reducer.

-

Operating Conditions: Monitor the gearbox and gear reducer's operating conditions, including temperature, vibration, and load levels, etc. So that potential problems can be detected early.

-

Overload Protection: Install overload protection mechanisms, such as torque limiters or sensors, to prevent gearbox damage in the event of unexpected load spikes or operational problems.

-

Training and Education: Train operators and maintenance personnel on proper gearbox operation, maintenance, and troubleshooting procedures to ensure optimum performance of transmissions and gear reducers.

By considering these factors when selecting a gearbox, ensuring proper sizing and compatibility, and following tips for optimum performance and service life, the performance and efficiency of the machinery or equipment can be optimized and the service life of the gearbox or gear reducer can be extended.

5. Conclusion

This paper describes the key role of gearboxes and reducers in improving the performance of machines. By exploring the functions of gearboxes and reducers and their benefits, this paper explains their importance in improving operational efficiency.

Gearboxes and gear reducers are the core components of machinery, and they help to transmit power accurately, adjust speed, and increase torque. They enable the speed of the power source to be matched to the requirements of the equipment, which not only improves performance but also helps to save energy, improve control, and extend equipment life.

6. Call to Action

To further optimize mechanical performance and meet specific requirements, we recommend readers visit www.tanhoncd.com for a wide range of gearboxes and reducers. Visitors can find a high-quality gear solution that meets their operational goals.

By utilizing the expertise and innovative technology offered by www.tanhoncd.com transmissions and gear motors, manufacturers can improve mechanical performance, reduce maintenance costs and increase overall operational efficiency.

7. External Links and Further Reading

-

For more in-depth information on gearboxes and gear reducers, you can refer to resources provided by the American Gear Manufacturers Association (AGMA).

-

Explore the latest advancements in gear technology and industry standards through the publications and research available from the International Organization for Standardization (ISO).

-

Stay updated on industry trends and innovations related to gear technologies by visiting Gear Technology Magazine for insightful articles and industry news.

-

Access valuable technical resources and research papers on gear design and manufacturing from the Society of Automotive Engineers (SAE) to enhance your understanding of gear systems and components.

Related News