How to Check the Gearbox and Gear Reducer Oil Level

Release time:

2024-07-22

Learn how to check the gearbox oil level with our step-by-step guide. Ensure optimal performance with tips from TanHonCD. Visit us for expert advice!

Introduction

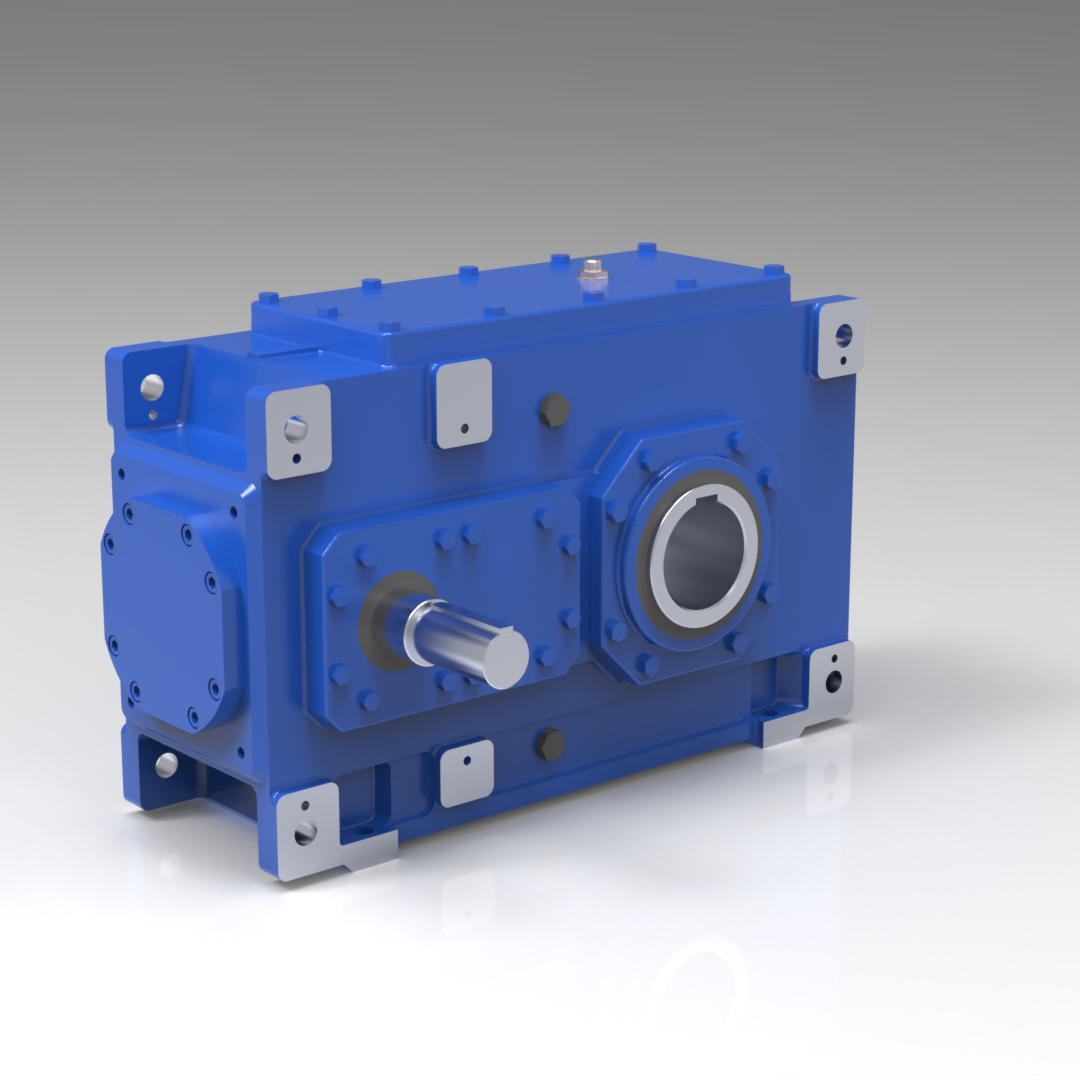

Proper gearbox maintenance, including regular oil level checks, is crucial for optimal performance and longevity. Tanhon Transmission Machinery Co., Ltd. specializes in providing high-quality gearboxes and offers professional guidance on their maintenance. This article will walk you through the steps to check your gearbox oil level effectively, ensuring your machinery operates smoothly and efficiently.

Understanding Gearbox Oil and its Function

What is Gearbox Oil?

Gearbox oil is a lubricant designed to lubricate gear systems, reducing friction and wear and ensuring smooth operation. Unlike engine oils, gearbox oils are formulated to handle the high pressure and metal-to-metal contact inside gearboxes, providing the necessary protection and performance for the gears.

Importance of Gearbox Oil

Gearbox oil plays a vital role in preventing wear and tear, reducing heat generated by friction, and ensuring the smooth operation of gears. It helps maintain optimal performance and extends the lifespan of your gearbox by minimizing the risk of metal fatigue and component failure. Learn more about the role of lubrication in gearbox maintenance here.

Signs Your Gearbox Oil Level Needs Checking

Common Symptoms

Knowing when to check your gearbox oil level can prevent minor issues from escalating into major problems. Common symptoms that indicate your gearbox oil level may be low include:

- Unusual Noise: Grinding or whining noises may indicate insufficient lubrication.

- Overheating: Excessive heat can indicate low oil levels, causing the gearbox to overheat.

- Performance Issues: Delayed gear shifts, slipping gears, or overall sluggish performance can be caused by low oil levels. Read more about gearbox issues.

Impact of Low Gearbox Oil Level

Ignoring these symptoms can lead to significant damage and operational inefficiency. Low oil levels can cause excessive friction, leading to increased wear and tear on the gears and potentially resulting in catastrophic gearbox failure. This can lead to costly repairs or even the complete replacement of the gearbox. Therefore, it’s essential to check and maintain proper oil levels regularly.

Tools and Safety Precautions for Checking Gearbox Oil Level

Necessary Tools

Before you start checking your gearbox oil level, gather the necessary tools:

- Gloves: To protect your hands from oil and grime.

- Oil Pan: To catch any oil that may spill during the process.

- Wrench or Socket Set: Remove the oil filler cap.

- Clean Cloth: This is used to wipe off excess oil and keep parts clean.

- Flashlight: To help see inside the filler hole if necessary.

Safety Precautions

Safety is paramount when working with machinery. Follow these precautions to ensure a safe and effective oil level check:

- Level Surface: Ensure the machinery is flat to prevent inaccurate readings.

- Cool Down: Allow the gearbox to cool down before checking the oil level to avoid burns from hot components.

- Protective Gear: Wear gloves and safety goggles to protect your hands and eyes from oil splashes.

- Secure the Machinery: Ensure the machinery is firmly supported and won’t move while you work. Follow these safety tips for gearbox maintenance.

Detailed Steps to Check Gearbox Oil Level

Locate the Gearbox Oil Filler Cap

The first step in checking your gearbox oil level is to locate the oil filler cap. The exact location can vary depending on the type of machinery, so it’s essential to refer to your specific manual. Generally, the oil filler cap is marked with a particular symbol or label and can often be found on the gearbox casing.

Prepare the Machinery

Preparation is critical to a booming oil level check. Follow these steps:

- Ensure Coolant Temperature: Ensure the gearbox is cool to the touch to avoid burns.

- Flat Surface: Position the machinery on a flat surface.

- Secure Environment: Ensure the area is well-lit and clutter-free to avoid accidents.

- Wear Protective Gear: Wear gloves and safety goggles to protect yourself during the inspection.

Remove the Oil Filler Cap

You can remove the oil filler cap once the machinery is prepared correctly. Use the appropriate wrench or socket set to unscrew the cap. Be cautious when removing it to prevent any oil from spilling out.

Check the Oil Level

Method Using a Dipstick

Many gearboxes come equipped with a dipstick for easy oil level checking. Here’s how to use it:

- Insert the Dipstick: Fully insert the dipstick into the oil filler hole.

- Pull Out the Dipstick: Remove the dipstick and check the oil level against the marked range.

- Read the Level: The oil level should be within the designated “full” and “low” markings. If it's below the minimum mark, it needs topping up.

Visual Inspection

For gearboxes that don’t have a dipstick, a visual inspection can be performed:

- Inspect Inside the Filler Hole: Look inside the oil filler hole with a flashlight.

- Check the Level: The oil should be up to the level of the filler hole. If it’s noticeably below, you need to add more oil.

Top Up if Necessary

If the oil level is low, follow these guidelines to top it up:

- Select the Right Gearbox Oil Type: Use the type specified in your machinery manual.

- Add Oil Gradually: Pour the oil slowly to avoid overfilling, periodically checking the level.

- Recheck the Level: Once topped up, recheck the oil level to ensure it’s within the correct range.

Replace the Filler Cap and Clean Up

After ensuring the oil level is correct:

- Secure the Oil Filler Cap: Screw the filler cap back on securely using the wrench or socket set.

- Clean Residual Oil: Wipe away any spilled oil around the filler area.

- Dispose of Used Oil Properly: If you replace some oil, ensure the used oil is disposed of according to local regulations.

Best Practices for Maintaining Gearbox Oil

Frequency of Checking and Changing Oil

The frequency of checking and changing gearbox oil can vary based on the type and usage of the machinery. General recommendations are:

- Light Machinery: Check every six months.

- Heavy Machinery: Follow the manufacturer's maintenance schedule, often based on operating hours.

- Industrial Gearboxes: Regularly monitor and replace oil as needed, typically every 1,000-3,000 operating hours.

Tips for Different Gearboxes

Different types of gearboxes require specific attention:

- Manual Gearboxes: Ensure the oil is topped up and replaced as needed to prevent gear wear.

- Automatic Gearboxes: Use the manufacturer’s recommended oil type and check levels more frequently.

- CVT Gearboxes: Ensure proper oil type and levels, as incorrect oil can lead to significant issues. Read about best maintenance practices.

Common Mistakes to Avoid

Using the Wrong Type of Oil

One of the most common mistakes is using the wrong type of oil. Always consult the machinery manual to ensure you use the recommended oil type. Using incorrect oil can lead to inadequate lubrication and potential damage.

Overfilling the Gearbox

Overfilling the gearbox can be just as damaging as low oil levels. It can cause increased air pressure inside the gearbox, leading to leaks and potential seal damage. Always ensure you add oil gradually and check levels periodically to avoid overfilling.

When to Seek Professional Help

Severe Oil Leaks

If you notice severe oil leaks or the oil level drops rapidly after topping up, it’s crucial to seek professional help. Severe leaks can indicate significant damage that requires expert diagnosis and repair.

Persistent Performance Issues

Persistent performance issues, such as difficulty shifting gears or unusual noises even after checking and topping up the oil, suggest deeper problems that need professional intervention. Tanhon Transmission Machinery Co., Ltd. specialists can efficiently diagnose and resolve complex gearbox issues.

Conclusion

Regularly checking your gearbox oil level is essential for maintaining your machinery's smooth operation and longevity. Following the detailed steps outlined in this guide, you can ensure your gearbox remains well-lubricated, reducing the risk of wear and tear and potential failure. Understanding the importance of gearbox oil, recognizing the signs that indicate a low oil level, and adhering to best practices in maintenance can save you from costly repairs and downtime. Remember, a well-maintained gearbox is crucial for the efficiency and reliability of your machinery.

Call To Action

For more expert tips and professional advice on gearbox maintenance, visit www.tanhoncd.com. Don’t hesitate to contact Tanhon Transmission Machinery Co., Ltd. for high-quality gearbox solutions and personalized guidance on maintaining your equipment. Whether you need advice on selecting the correct type of gearbox oil or professional help to address complex performance issues, Tanhon's support team is here to assist you. Contact Tanhon today and ensure your gearbox operates at its best!

FAQs

How often should I check my gearbox oil level?

It’s recommended to check the gearbox oil level every six months or according to the manufacturer’s guidelines. Regular checks help ensure the gearbox operates smoothly and efficiently.

What type of oil should I use for my gearbox?

Consult your machinery manual for the recommended type of gearbox oil, as it varies based on make and model. Using the specified oil type ensures proper lubrication and performance.

What are the signs of low gearbox oil?

Symptoms of low gearbox oil include increased noise, overheating, and difficulty shifting gears. Regularly checking the oil level can help identify and address these issues early.

Can I check the gearbox oil level myself?

Yes, with the proper tools and following safety precautions, you can check the gearbox oil level yourself. This article provides a detailed guide on how to do it effectively.

What happens if the gearbox oil level is too low?

Low gearbox oil levels can cause increased friction, overheating, and eventual gearbox failure. Regular checks and maintenance can prevent these issues and prolong the life of your gearbox.

Related News