How to Determine the Right Gear Reducer for Your Application

Release time:

2024-07-19

Learn how to choose the right gear reducer for your application by understanding torque, gear ratio, and environmental factors. Get practical advice and explore Tanhon's offerings.

Selecting the right gear reducer is crucial for optimal performance and efficiency. Gear reducers play a vital role in various industrial applications by adapting torque and speed to meet specific requirements. The complexity and variety of gear reducers available can make the selection process challenging. Understanding the importance of this decision can lead to significant cost savings and improved operational efficiency. Explore Tanhon for top-quality gear reducers! This blog aims to provide a comprehensive guide to help you make an informed choice.

Understanding Gear Reducers

Gear reducers, also known as gear reducers, play a pivotal role in various industrial applications. These devices adapt the torque and speed of machinery to meet specific operational requirements. The basic construction of a gear reducer involves a large gear positioned with a smaller gear, both turning together. This configuration reduces the speed produced by the machinery to a practical level for the powered application.

Gear reducers, also known as gear reducers, play a pivotal role in various industrial applications. These devices adapt the torque and speed of machinery to meet specific operational requirements. The basic construction of a gear reducer involves a large gear positioned with a smaller gear, both turning together. This configuration reduces the speed produced by the machinery to a practical level for the powered application.

I would like to introduce the article What Are the Gearbox and Gear Reducer for reference to learn the basic knowledge of the gearbox and gear reducer.

Types of Gear Reducers

Different types of gear reducers cater to various needs. Each type offers unique advantages based on the application.

Bevel Gear Reducers

Bevel gear reducers are compact and robust. They handle significant power, making them ideal for high-torque applications. The robustness of their teeth allows usage with three-phase asynchronous motors, synchronous motors, or asynchronous servomotors.

Gear Train Gear Reducers

Gear train gear reducers modify the speed and torque of rotating equipment. These reducers find extensive application across diverse manufacturing, automotive, and aerospace industries. Precise control of machinery speed and output is paramount in these sectors.

General Gear Reducers

General gear reducers exponentially increase torque based on the number of gears in the system and the number of teeth in each gear. Devices requiring rapid acceleration benefit significantly from this type of gear reducer.

Applications of Gear Reducers

Gear reducers transmit power and control the speed of machinery in many industrial applications. Whether designing a new system or upgrading an existing one, choosing the right gear reducer is essential for optimal performance and efficiency.

-

Manufacturing: Ensures precise control of machinery speed and output.

-

Automotive: Adapts torque and speed for various automotive components.

-

Aerospace: Provides reliable power transmission and speed control.

Conclusion

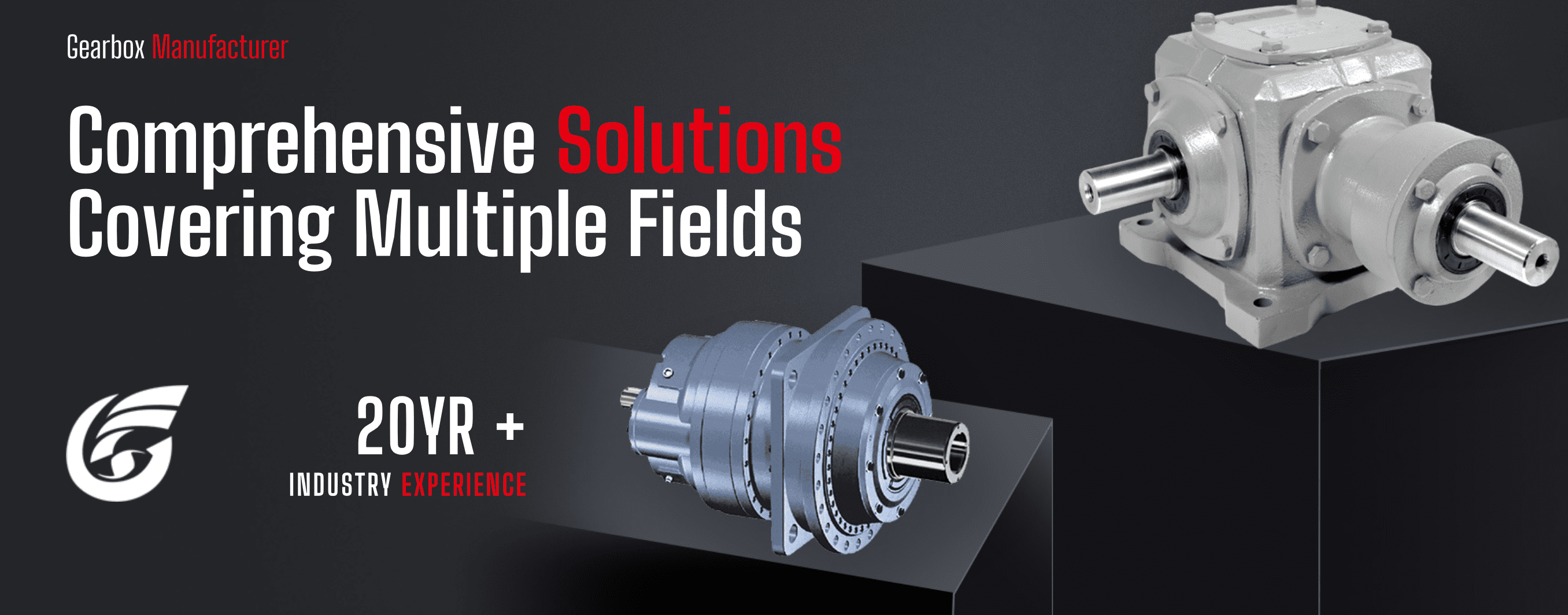

Understanding the different types of gear reducers and their applications helps select the right one for specific needs. Tanhon Transmission Machinery Co., Ltd offers a wide range of gearboxes and reducers, including standard and non-standard options. With over 20 years of expertise, Tanhon provides reliable solutions for various industrial applications.

Key Factors to Consider

Torque Requirements

Calculating Torque

Calculating torque is essential for selecting the right gear reducer. Torque represents the rotational force applied to a system. The formula for calculating torque involves multiplying the force applied by the distance from the pivot point. Engineers must consider the specific requirements of the application to ensure accurate calculations.

Matching Torque to Application

Matching torque to the application ensures optimal performance. Different applications require varying levels of torque. High-torque applications, such as heavy machinery, demand robust gear reducers. Low-torque applications, like small conveyors, need less powerful gear reducers. Correctly matching torque prevents equipment failure and enhances efficiency.

Gear Ratio Requirements

Importance of Gear Ratio

The gear ratio determines the relationship between input speed and output speed. A higher gear ratio reduces the output speed while increasing torque. Conversely, a lower gear ratio increases output speed but reduces torque. Understanding the importance of gear ratio helps achieve the desired performance for specific applications.

How to Calculate Gear Ratio

Calculating the gear ratio involves dividing the number of teeth on the output gear by the number of teeth on the input gear. This calculation provides the ratio needed to achieve the desired speed and torque. Accurate gear ratio calculations ensure the gear reducer meets the machinery's operational requirements.

Scientific Research Findings

-

Understanding Torque and Speed in Gear Reducers: Gear reducers are essential for adapting torque and speed in mechanical systems.

-

Choosing the Right Gear Reducer for Your Application: Selecting the appropriate gear reducer involves considering torque, rotation speed, and the ability to handle specific inertial loads.

-

The Functionality of Gear Reducers in Torque Management: Gear reducers play a vital role in adjusting gear speeds to generate torque.

-

Advantages of Gear Reducers in Torque Enhancement: Gear reducers enable the achievement of high torque, low speeds, and efficient handling of inertial loads using smaller motors.

-

Factors to Consider When Selecting Gear Reducers: The crucial factor in choosing a gear reducer is the balance between torque and rotation speed.

Tanhon Transmission Machinery Co., Ltd offers various gear reducers tailored to meet various industrial needs. With over 20 years of expertise, Tanhon provides reliable solutions for different torque and speed requirements.

Selecting the Right Type of Gear Reducer

Application-Specific Considerations

Load Type

Understanding the load type is crucial for selecting the appropriate gear reducer. Different applications involve varying load types, such as constant, variable, and shock loads. Constant loads require gear reducers that provide steady performance over time. Variable loads demand gear reducers that can adapt to changing conditions. Shock loads necessitate robust gear reducers capable of withstanding sudden impacts. Tanhon Transmission Machinery Co., Ltd offers gear reducers to handle diverse load types, ensuring optimal performance.

Speed Requirements

Speed requirements play a significant role in choosing the right gear reducer. High-speed applications need gear reducers that can maintain efficiency at elevated speeds. Low-speed applications benefit from gear reducers that provide high torque at reduced speeds. Accurate speed calculations help in selecting gear reducers that meet specific operational needs. Tanhon's extensive range of gear reducers caters to various speed requirements, from high-speed machinery to low-speed conveyors.

Environmental Factors

Operating Conditions

Operating conditions influence the selection of gear reducers. Factors such as temperature, humidity, and exposure to corrosive substances impact gear reducer performance. High-temperature environments require gear reducers with heat-resistant materials. Humid conditions necessitate gear reducers with corrosion-resistant coatings. Tanhon provides gear reducers designed to operate efficiently under diverse environmental conditions, ensuring durability and reliability.

Maintenance Needs

Maintenance needs should be considered when selecting gear reducers. Some applications require gear reducers with minimal maintenance, while others can accommodate more frequent servicing. Gear reducers with self-lubricating features reduce maintenance efforts. Easy-access designs facilitate quicker inspections and repairs. Tanhon's gear reducers offer various maintenance options, allowing users to choose products that align with their maintenance capabilities and schedules.

Practical Advice for Decision-Making

Consulting with Experts

When to Seek Professional Help

Consulting experts becomes essential when facing complex gear reducer requirements. Engineers often encounter unique challenges that require specialized knowledge. Tanhon Transmission Machinery Co., Ltd offers expert consultation services. Their team provides valuable insights tailored to specific industrial needs. Seeking professional help ensures accurate gear reducer selection, preventing costly mistakes.

Questions to Ask

Asking the right questions during consultations enhances decision-making. Key questions include:

-

What type of gear reducer suits the application best?

-

How do environmental factors affect gear reducer performance?

-

What maintenance requirements should be anticipated?

-

How does the load type influence gear reducer selection?

These questions guide discussions, ensuring comprehensive understanding and informed choices.

Using Manufacturer Resources

Product Catalogs

Manufacturers provide detailed product catalogs that serve as valuable resources. These catalogs offer various gear reducers' specifications, features, and application guidelines. Tanhon's catalog includes 16 series of standard and non-standard gearboxes and reducers. Reviewing these catalogs helps identify suitable products based on specific requirements.

Online Tools and Calculators

Online tools and calculators simplify the selection process. These resources assist in calculating torque, gear ratios, and other critical parameters. Tanhon's website features user-friendly tools designed to aid engineers in making precise calculations. Utilizing these tools ensures accurate gear reducer selection, enhancing operational efficiency.

Case Studies

Successful Implementations

Industrial Applications

Worm Gear Reducers have proven effective in various industrial settings. These reducers offer high transmission ratios and operate quietly. Conveyor systems benefit significantly from worm gear reducers due to their non-reversibility. This feature ensures consistent and reliable operation, preventing back-driving issues. Winches also utilize worm gear reducers to handle heavy loads with precision. Material handling equipment often incorporates these reducers to achieve smooth and controlled movement.

Bevel Gear Reducers are extensively used in high-torque applications. Manufacturing plants rely on bevel gear reducers to manage heavy machinery. These reducers provide robust performance and durability, ensuring minimal downtime. The automotive industry employs bevel gear reducers to adapt torque and speed for different components. Aerospace applications benefit from the precise control offered by these reducers, enhancing the reliability of critical systems.

Commercial Applications

Gear Train Reducers play a vital role in commercial applications. Retail conveyor belts use gear train reducers to maintain consistent speed and torque. This ensures efficient product movement and reduces operational costs. Packaging machinery benefits from gear train reducers by achieving precise control over speed and output. This results in higher productivity and reduced waste. HVAC systems incorporate gear train reducers to regulate fan speeds, improving energy efficiency and system longevity.

General Gear Reducers enhance performance in various commercial settings. Elevators utilize general gear reducers to achieve smooth and safe operation. These reducers provide the necessary torque to lift and lower elevator cars efficiently. Escalators also benefit from general gear reducers, ensuring reliable and consistent movement. Automated doors in commercial buildings use these reducers to control opening and closing speeds, enhancing user safety and convenience.

Lessons Learned

Common Mistakes

One common mistake involves selecting a gear reducer without considering the specific load type. Engineers must understand whether the application involves constant, variable, or shock loads. Choosing the wrong gear reducer can lead to premature failure and increased maintenance costs. Another mistake is neglecting environmental factors. High temperatures, humidity, and corrosive substances can impact gear reducer performance. Selecting gear reducers without accounting for these conditions can reduce efficiency and lifespan.

Best Practices

Engineers should follow best practices when selecting gear reducers to avoid common mistakes. First, accurately calculate torque and speed requirements. This ensures the chosen gear reducer meets the application's demands. Second, consider the operating environment. Select gear reducers with appropriate materials and coatings to withstand harsh conditions. Third, consult with experts when facing complex requirements. Professional advice can prevent costly errors and ensure optimal performance.

Tanhon Transmission Machinery Co., Ltd offers various gear reducers to meet diverse industrial and commercial needs. With over 20 years of expertise, Tanhon provides reliable solutions tailored to specific applications. Their extensive product catalog and expert consultation services help engineers make informed decisions, ensuring successful implementations and long-term efficiency.

Overview of Tanhon Gear Reducers

Product Range

Tanhon - Your Gearbox and Gear Reducer Experts! offers a diverse range of gear reducers tailored to meet various industrial needs. The product range includes standard and non-standard gearboxes, ensuring flexibility for different applications.

Key Features

Tanhon's gear reducers boast several key features:

-

High Efficiency: Designed to maximize performance while minimizing energy consumption.

-

Durability: Constructed with robust materials to withstand harsh operating conditions.

-

Versatility: Suitable for various applications, from manufacturing to aerospace.

-

Precision: Engineered for accurate torque and speed control, essential for high-performance machinery.

Specifications

Each gear reducer in Tanhon's catalog comes with detailed specifications to guide selection:

-

Torque Capacity: Ranges from low to high, catering to different power requirements.

-

Gear Ratios: These are available in various ratios to match specific speed and torque needs.

-

Material Composition: Options include heat-resistant and corrosion-resistant materials.

-

Size and Weight: Compact designs for space-constrained environments and larger models for heavy-duty applications.

Customer Support

Tanhon - Your Gearbox and Gear Reducer Expert prioritizes customer satisfaction through comprehensive support services.

Technical Assistance

Tanhon provides expert technical assistance to help customers select the right gear reducer. The support team offers:

-

Consultation Services: Expert advice on choosing gear reducers based on application requirements.

-

Installation Guidance: Step-by-step instructions for proper installation to ensure optimal performance.

-

Troubleshooting Help: Solutions for common issues to minimize downtime and maintain efficiency.

Warranty and Service

Tanhon backs its products with reliable warranty and service options:

- Warranty Coverage: Comprehensive warranties that cover defects and ensure peace of mind.

-

Maintenance Services: Regular maintenance plans to extend the lifespan of gear reducers.

-

Repair Services: Prompt repair services to address any issues and restore functionality quickly.

Future Trends in Gear Reducers

Technological Advancements

Smart Gear Reducers

Smart gear reducers represent a significant advancement in the field. These devices integrate sensors and IoT technology to monitor performance in real time. Engineers can use data analytics to predict maintenance needs and optimize operations. This proactive approach reduces downtime and extends the lifespan of machinery. Tanhon Transmission Machinery Co., Ltd offers smart gear reducers with advanced monitoring capabilities. These products provide valuable insights into operational efficiency.

Energy Efficiency

Energy efficiency remains a critical focus in gear reducer development. Manufacturers aim to design gear reducers that minimize energy consumption while maintaining high performance. Innovations in materials and lubrication techniques contribute to this goal. High-efficiency gear reducers reduce operational costs and support sustainability initiatives. Tanhon's gear reducers feature energy-efficient designs, ensuring optimal performance with minimal energy use.

Market Trends

Industry Growth

The gear reducer market continues to experience robust growth. Increased automation across industries drives demand for reliable and efficient gear reducers. Manufacturing, automotive, and aerospace sectors rely on these devices to precisely control machinery. The rise in renewable energy projects also boosts the need for specialized gear reducers. Tanhon Transmission Machinery Co., Ltd caters to this growing market with diverse products tailored to various industrial applications.

Emerging Applications

Emerging applications present new opportunities for gear reducer technology. Robotics and autonomous systems require compact and high-performance gear reducers. Medical devices benefit from gear reducers that offer precision and reliability. The agricultural sector increasingly adopts gear reducers for advanced machinery. Tanhon's extensive product range includes solutions for these emerging applications, ensuring adaptability and innovation in diverse fields.

FAQs about Gear Reducers

Common Questions

Installation Tips

Proper installation ensures optimal performance and longevity of gear reducers. Follow these steps for successful installation:

-

Alignment: Ensure precise alignment between the motor and the gear reducer. Misalignment can cause excessive wear and reduce efficiency.

-

Mounting: Securely mount the gear reducer to a stable, vibration-free surface. Use appropriate mounting hardware to prevent movement.

-

Lubrication: Apply the recommended lubricant before operation. Regularly check and maintain lubrication levels to prevent overheating and wear.

-

Electrical Connections: Verify all electrical connections are secure and meet the manufacturer's specifications. Loose connections can lead to operational failures.

-

Testing: Perform a test run to check for unusual noises or vibrations. Address any issues immediately to avoid long-term damage.

Troubleshooting

Common issues with gear reducers can often be resolved with basic troubleshooting steps:

-

Noise: Unusual noise may indicate misalignment or insufficient lubrication. Check alignment and lubrication levels.

-

Overheating: Overheating can result from excessive load or inadequate ventilation. Reduce the load and ensure proper airflow around the gear reducer.

-

Vibration: Excessive vibration may stem from loose mounting or imbalanced components. Tighten mounting hardware and inspect for imbalances.

-

Leakage: Oil leakage can occur due to worn seals or overfilled lubricant. Replace seals and adjust lubricant levels as needed.

-

Performance Drop: A drop in performance may indicate internal wear or damage. Inspect internal components and replace any worn parts.

Expert Answers

Technical Insights

Experts emphasize the importance of understanding specific application requirements. Different types of gear reducers, such as planetary, worm, gear train, and bevel gear reducers, offer unique advantages. For instance, planetary gear reducers provide high torque and compact size, making them suitable for space-constrained applications. Worm gear reducers provide quiet operation and high transmission ratios, ideal for conveyor systems.

Engineers recommend considering input and output shaft configurations when selecting gear reducers. Proper configuration ensures compatibility with existing machinery and enhances overall performance. Tanhon Transmission Machinery Co., Ltd offers various configurations to meet diverse industrial needs.

Practical Advice

Designers suggest regular maintenance to extend the lifespan of gear reducers. Scheduled inspections and timely replacements of worn components prevent unexpected failures. Utilizing gear reducers with self-lubricating features reduces maintenance efforts and enhances reliability.

Industry Professionals advise consulting manufacturer resources for accurate selection. Tanhon's product catalog and online tools provide detailed specifications and calculation aids. Leveraging these resources ensures precise gear reducer selection tailored to specific operational requirements.

Tanhon Transmission Machinery Co., Ltd, with over 20 years of expertise, offers reliable ODM & OEM solutions. Their extensive range includes standard and non-standard gearboxes and reducers, ensuring flexibility for various applications.

Additional Resources

Books and Publications

Recommended Reading

Books provide in-depth knowledge about gear reducers and their applications. "Gear Reduction Systems: Design and Application" by John Smith offers comprehensive insights into gear reducers' design principles and practical applications. "Industrial Gear Reducers: Selection and Maintenance" by Robert Brown covers essential topics such as selection criteria, maintenance practices, and troubleshooting techniques. These books serve as valuable resources for engineers and technicians seeking to deepen their understanding of gear reducers.

Industry Journals

Industry journals publish the latest research and developments in gear reducer technology. "Journal of Mechanical Design" features peer-reviewed articles on innovative gear reducer designs and applications. "International Journal of Advanced Manufacturing Technology" includes studies on integrating gear reducers in advanced manufacturing processes. Subscribing to these journals keeps professionals updated on emerging trends and technological advancements.

Online Resources

Websites and Forums

Websites and forums offer a wealth of information and community support for gear reducer enthusiasts. DirectIndustry's Guide provides detailed articles on choosing the right gear reducer, including types and selection criteria. Bauer GMC's website features practical advice on gear ratio significance and its impact on performance. Forums like Eng-Tips and Mechanical Engineering Forum allow professionals to discuss challenges, share solutions, and seek advice from peers.

Educational Videos

Educational videos visually demonstrate the principles and applications of gear reducers. YouTube channels such as "Engineering Explained" offer tutorials on calculating torque and gear ratios. Tanhon Transmission Machinery Co., Ltd's official channel showcases product demonstrations and installation guides for their gear reducers. Watching these videos helps engineers and technicians apply complex concepts effectively in real-world scenarios.

Tanhon Transmission Machinery Co., Ltd, with over 20 years of expertise, provides a wide range of gear reducers tailored to various industrial needs. Their extensive product catalog and expert consultation services ensure customers receive reliable and efficient solutions for their specific applications.

Selecting the right gear reducer ensures optimal performance and efficiency. Applying the guidelines in this blog can help achieve the best results for specific applications. Explore Tanhon for top-quality gear reducers! Tanhon - Your Gearbox and Gear Reducer Experts! offers a wide range of products and professional advice. Share this blog or leave comments to engage with the community and enhance your knowledge.

Related News